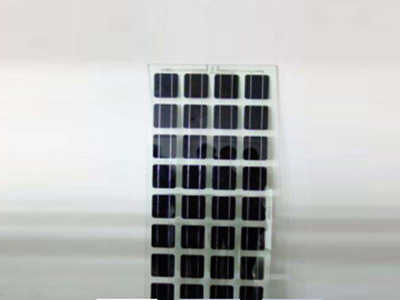

The double glass module cover plate commonly uses 2.0mm or 2.5mm ultra white embossed solar tempered coated glass (our company can make the thinnest glass 1.6mm). The thinner the cover glass, the higher its transmittance, thereby improving the output power of the entire module. The back panel uses ordinary float glass with a thickness of 2.0mm-6.0mm instead of TPT back panel. The glass back panel can be punched or not punched according to customer needs. No aluminum frame is required, which has a significant cost advantage over traditional components.

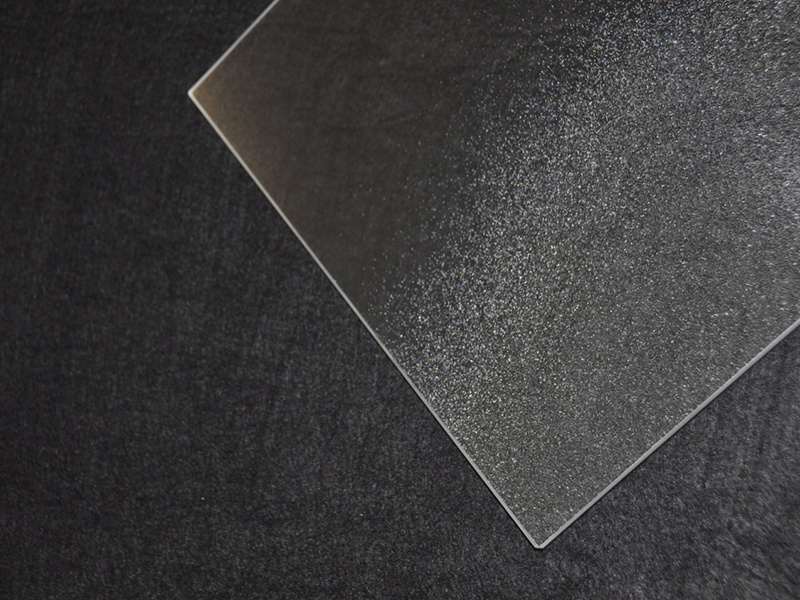

This anti reflective film is based on advanced nanoporous silica technology. By controlling the size and stacking morphology of silica particles, a nano scale uniformly distributed porous nanomaterial is obtained on the surface of ultra white glass. The reflectivity of the film layer is reduced to about 1%, greatly reducing the reflectivity of solar energy and improving the solar transmittance, ultimately enhancing the conversion efficiency of solar modules.

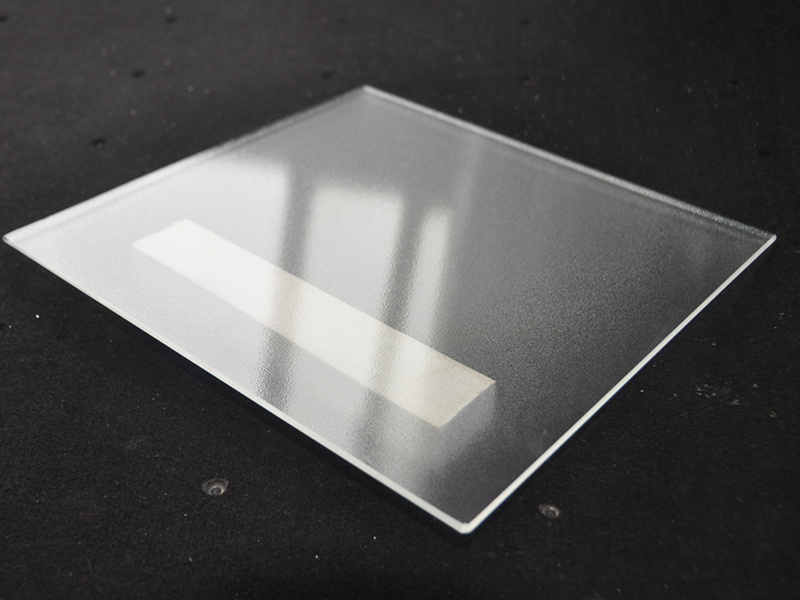

High transparency photovoltaic glass tempered sheet

Ultra white photovoltaic glass belongs to ultra white rolled glass, also known as ultra white textured glass, mainly used in solar cell packaging glass and is a component of solar photovoltaic cells. It has excellent characteristics such as high solar transmittance, low absorption, low reflectivity, and low iron content. It is a packaging material for solar photovoltaic and photothermal conversion systems, which can greatly improve the efficiency of photovoltaic and photothermal conversion.

High Transparency Photovoltaic Glass

The non-toxic formula of the product applied to ultra white photovoltaic glass fully meets the strict environmental requirements of Europe, the United States, and Japan, and is a packaging material for solar photovoltaic modules and solar thermal modules.