From bulletproof glass to float glass to vaccine bottles, all the miracles of the Chinese people depend on themselves!

Release time:

2021-08-03

On the occasion of the 100th anniversary of the founding of the Communist Party of China, the State-owned Assets Supervision and Administration Commission of the State Council and the Central Radio and Television Station jointly launched the 100-episode micro-documentary "A Hundred Years of Credential", with "Red Credential" as the starting point, 100 state-owned enterprises represented by central enterprises The person in charge of the enterprise party committee (party group) introduces the family heirloom of the enterprise, and reveals the little-known, carry forward the red tradition and inherit the red gene.

"The Hundred Years".

China's first car bulletproof glass

Zhou Yuxian, Party Secretary and Chairman of China National Building Materials Group

As a keep narrator

Introduced the original intention of China's glass industry.

and the course of innovation and development

This piece of glass

Weight over 169kg

The thickness reached 7.5cm

Equivalent to ten times the ordinary car glass now

Comrade Mao Zedong was personally concerned

Also personally ride in the red flag car with this bulletproof glass

What is the story behind this bulletproof glass?

Bulletproof Glass:

Escort the development of new China's diplomatic cause

At the beginning of the founding of New China, it was the Soviet-made "Gis" car that undertook the important task of ensuring the safety of the concierge in diplomatic activities. In 1966, when Comrade Chen Yi went to report to Chairman Mao on the newly produced domestic red flag car, Chairman Mao was very happy to see the brand-new domestic car, but then said: When we received foreign guests, the courtesy car was still a bulletproof car sent by the Soviet Union. When can we produce it ourselves?

Since then, China Building Materials Institute has opened the trial production task of automobile bulletproof glass. Under the historical conditions at that time, there was no good way to manufacture glass. Only refractory materials could be used to form a large crucible. Glass was melted in the large crucible. Fuel oil was used to heat the glass to 1400 degrees. The raw materials of the glass were turned into glass molten slurry, poured into a flat mold to become a blank. Then the blank of about 45mm was ground and polished to a thickness of 25mm, take out the best part of the essence of the blank for processing. At that time, the work efficiency was low, the time period was long, and the yield was low, but even under such unfavorable conditions, the China Building Materials Institute still made this piece of glass.

At that time, the confidentiality level of the project was quite high, and few people knew about it except the dean and the general manager. Later, there was always a big red flag driving in and out of the hospital to take away the finished glass products. Only then did everyone have some speculation, but no one said it clearly. Comrades all have a sense of honor and mission, knowing that this is making bulletproof glass for foreign guests and top leaders. In the end, all the data and materials are submitted, there is no award, the evaluation title is not allowed to be mentioned, and it is not even included in the scientific research projects and achievements of the unit.

This is the older generation of building materials, Mo Wen harvest, but ask hard work.

Solve the combustion chamber temperature problem

-- get into the tanker to dig for oil

A building materials institute held a staff meeting of the whole room to convey the instructions of the superior, hoping to produce more bulletproof glass as soon as possible and actively fight.

At that time, Comrade Chen Yongding of the mezzanine team never complained of hardship and was not afraid of tiredness. He pointed out that because of the cold weather, the fuel cannot be transported in, the consumption of coal is too large to meet the melting requirements, and the fuel cannot keep up, the fired products may be scrapped, resulting in greater waste; at the same time, the temperature of the combustion chamber does not go up, and molten glass water will leak out from time to time when stirring at high temperature, which not only affects the melting quality, but also hurts people. So we organized everyone to go to Tongzhou railway station, get into the tanker, to dig out the solidified fuel, everyone hungry to dig out the oil block into the oil drum. Because the weather is too cold, had to hide in the heating ditch. Under such difficult conditions, the fuel problem was solved and the melting work was guaranteed.

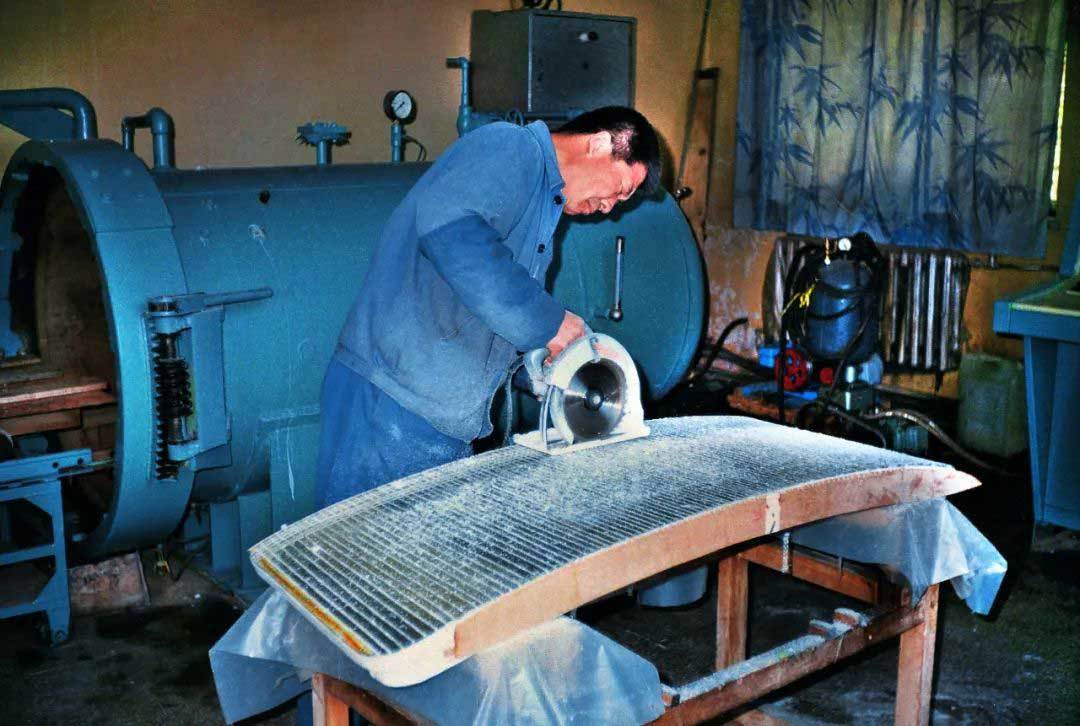

Testing the performance of bulletproof glass

-- Three shots of the West Hill

After the bulletproof glass was produced, Xu Zengzuo, director of the sandwich room, Zhu Shiliang, military representative, Song Wushan, head of the sandwich team, and Guo Yingshi, a member of the team, took the window sample side window glass and followed several people from Zhongnanhai Guard Company to the inspection site to test the bulletproof performance of the glass. At a distance of 100 meters, 3 shots were tested with 7.62mm armor-piercing bullets, which were fired by guards. Guo Yingshi was on standby to install and remove glass in the trench under the target. He saw with his own eyes that the first bullet fell in the trench; the second bullet was embedded in the glass, and the third bullet pushed the second bullet forward out of the glass, but only the bullet leaked out and did not penetrate. The guards all praised our inspection glass with admiration.

Float Glass:

Opening the Road of Independent Innovation of China's Glass Industry

In February 1959, the British Pilkington (Pilkington) Brothers announced to the world the success of the new process of producing flat glass by float, and built the world's first float glass production line in the UK. For a time, the world glass industry set off a share of "float crazy".

In 1964, China sent a group of experts to the United Kingdom to discuss the introduction of float technology. However, people do not let us touch any technology of float glass at all. Even if they want to spend money on glass samples, they politely refuse. There are even British people arrogantly said: it is too early to talk about float technology with red China. The arrogance and technological blockade of the West have greatly stimulated us. Everyone has gradually realized that the development and production of float glass in China must take the road of self-reliance and independent innovation, and must not pin their hopes on others.

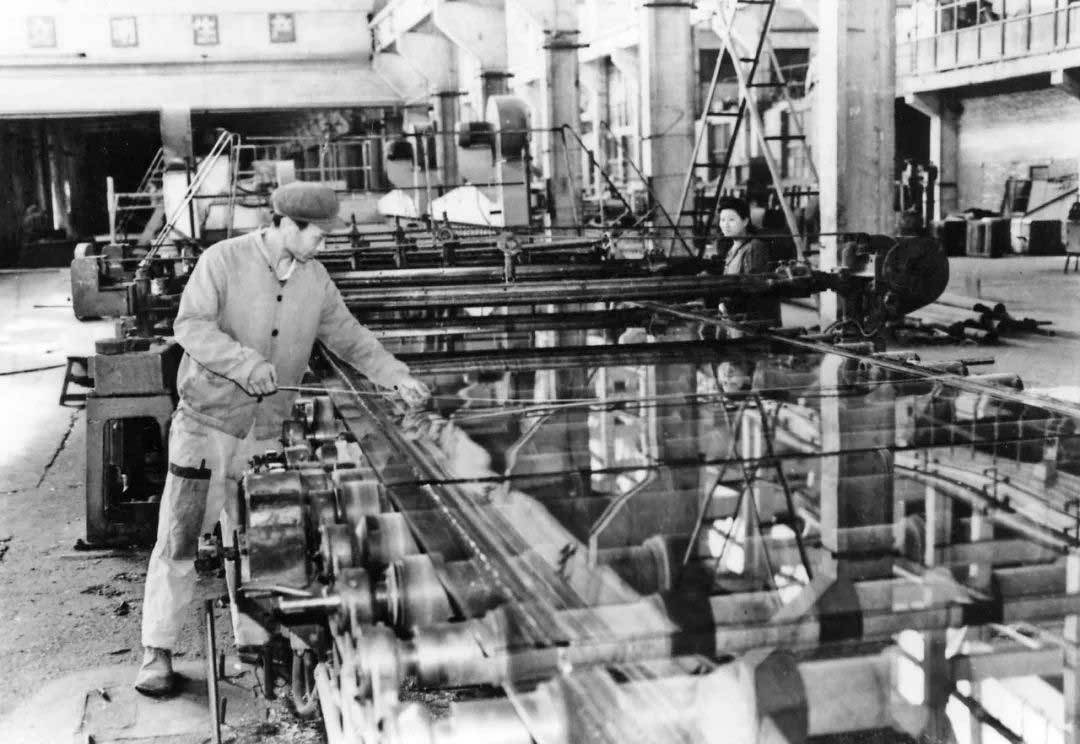

Beginning in May 1965, under the organization of the Ministry of Building Materials Industry, China began the research and experiment of float glass. The older generation of building materials started from scratch, conducted in-depth research and repeated tests, and overcame a series of unimaginable process and technical problems. After 6 years of hard work, they successively completed laboratory tests and semi-industrial intermediate tests, figured out the direction and strengthened their confidence.

Overcome difficulties in the "three without less" situation

-"Zhao Ba" refused to receive 500 overtime pay

The production of float glass is a technological revolution, this process is much better than the rolling method and the introduction of the method, glass flatness, strength, transparency, production efficiency will be greatly improved. Under the circumstances of "no technology, no data, no experience, and lack of funds, we have begun a" continuous rotation "type of arduous struggle. Without a design room, experts and technicians started to design and draw sketches on several tables in the boiler room. Without large lathe equipment, Lobo's fitters cut down the annealing kiln of the calendering line to process a 25-meter tin bath on site by means of a tinker mending the pot. An important problem encountered at that time was that high-temperature glass water was easy to condense when passing through the tin bath, resulting in uneven glass thickness. Sometimes the glass water ran and splashed in the tin trough, like a "dragon dance". The workers were scalded beside the 1000-degree kiln and tin trough, even though they were wearing thick cotton-padded jackets.

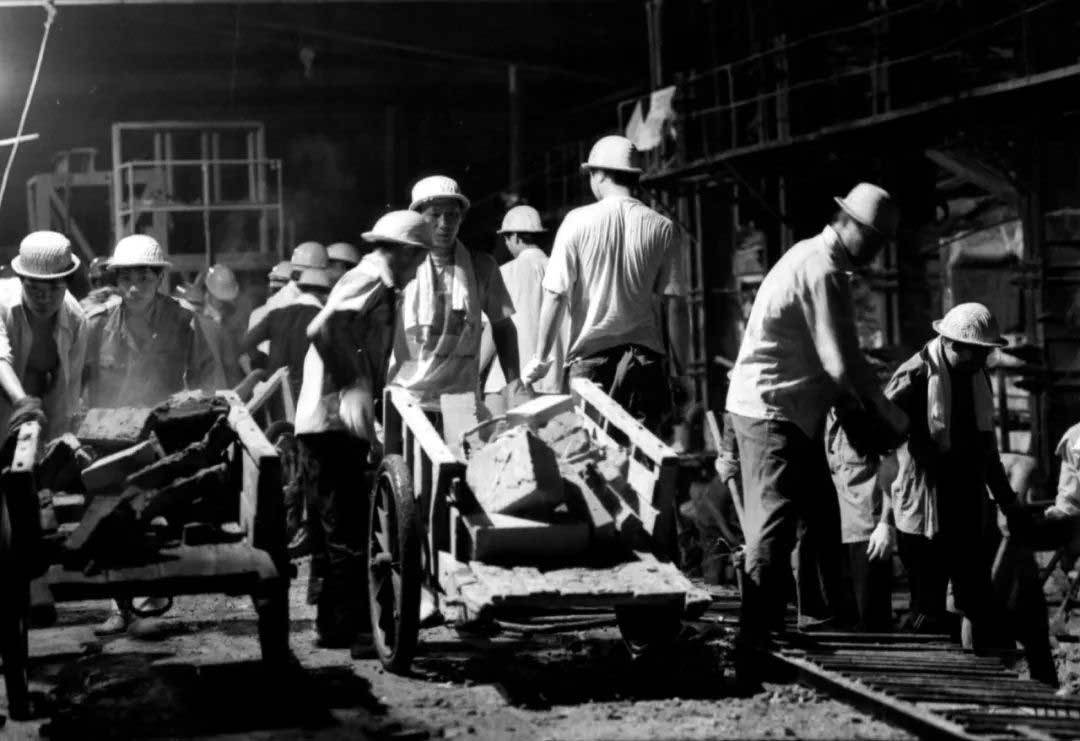

(In 1956, the fiery labor scene when the construction of Luoyang Glass Factory began)

Zhao Jiukui, a fitter in the machine repair workshop of Luoyang Glass Factory, who has won the provincial and municipal labor model for many times and was named as the "national worker technical innovation expert". At that time, he was the only "eighth-level fitter" in Luobo. Everyone affectionately called him "Zhao Ba". The difficult problems in the experimental production of float glass industry have become the battlefield for him to show his skills. He has been fighting day and night on the front line of production, constantly overcoming difficulties, and has become the "tinker" in the minds of employees-everything, the critical moment "Jin Gangzuan"-any difficulty can be solved. Lung disease committed, he did not tell anyone, coughed and blushed, he still insisted on not leaving the float production line day and night. The original three-month construction task, he and everyone worked overtime and worked hard together, and it took only 75 days to successfully pull out the crystal clear float glass. Later, the factory gave him 500 overtime to be rewarded, which he firmly refused with a wave of his hand. At that time, Li Jinlet, the section chief of the float line (later became the deputy general manager of Luobo Group), said excitedly: "Zhao Ba" can be said to be the representative of Luobo model workers. At that time, we did not admit defeat in our hearts and had to do it. We had no idea of overtime pay.

Glass Experts Gathers Thousands of Employees in Luobo

-- Built China's first float glass production line

In May 1971, the Ministry of Building Materials decided to carry out the float glass industrial test in Lobo. Glass experts from all over the country gathered in Lobo, and more than 1,000 employees of Lobo enthusiastically participated in the war. After more than three months of hard work, on September 23, 1971, China's first float glass production line was finally successfully built in Luoyang Glass Factory, producing China's first high-quality float glass and creating one of the world's three major float processes. This is a production line that strives for glory for the country and the nation. Its completion embodies the painstaking efforts and wisdom of leaders at all levels, technicians, and the broad masses of workers. They cherish the "great man of the country" and fight desperately. If there are no conditions to create conditions, they will finally usher in a new dawn for the development of China's national glass industry.

(Lobo float first-line cold end production site in the 1980 s)

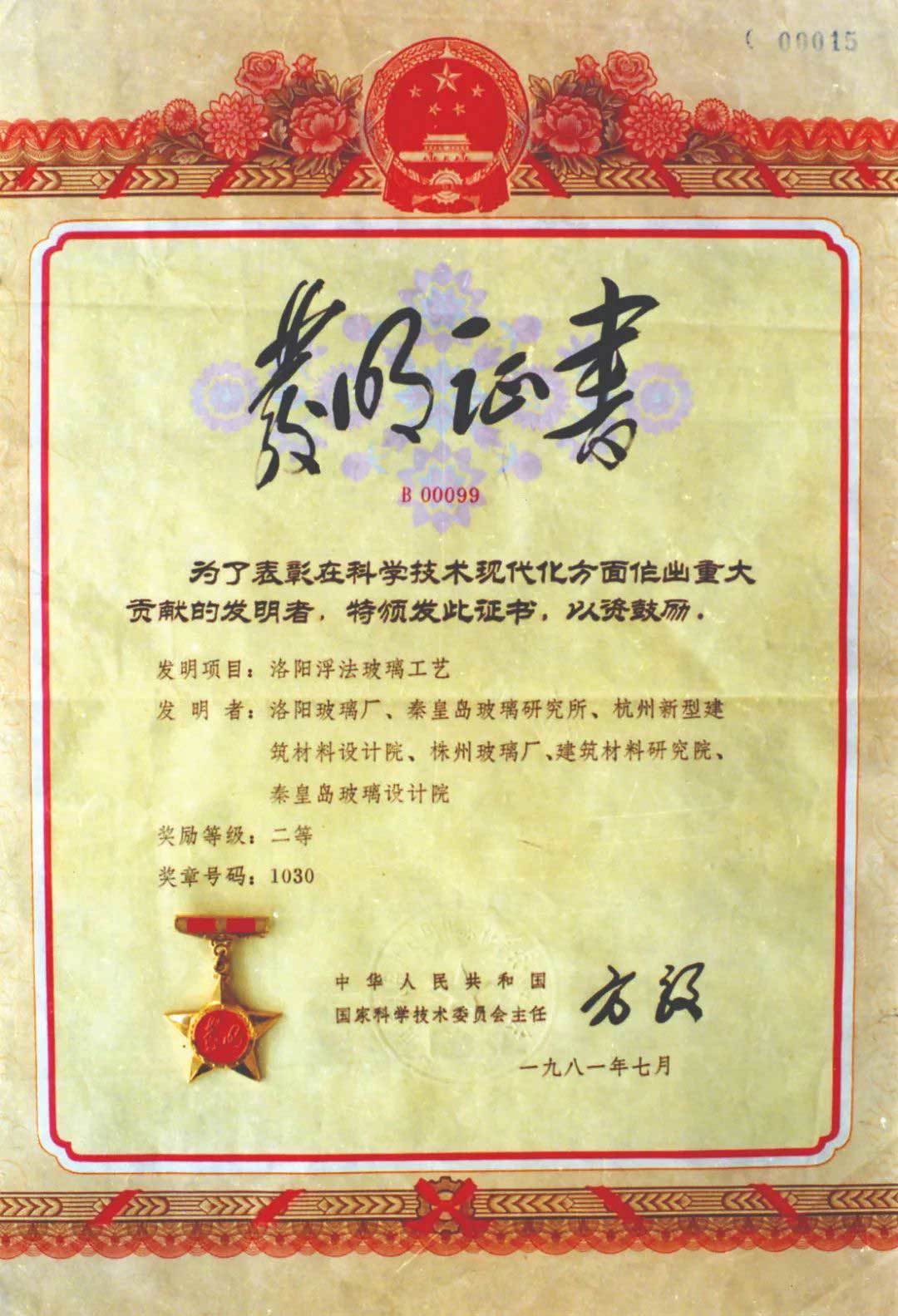

(In 1981, "Luoyang float glass technology" was awarded the second prize of creation and invention, and awarded the gold invention medal)

With the needs of economic and social development and technological progress, China has launched a plan to build a float line of more than 400 tons. At 11 o'clock on July 3, 1985, the second float line of Lobo was completed and put into operation, which achieved a major breakthrough in China's "Luoyang float glass technology" from small to large. In July 1989, Lobo "400-ton float glass production technology and equipment" was awarded the "first prize for scientific and technological progress". This is the first national "first prize for scientific and technological progress" in China's building materials industry ".

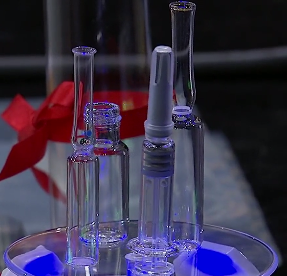

medicinal glass:

Break through the "stuck neck" to the world

The core of the manufacture of vaccine bottles lies in the manufacture of neutral borosilicate glass tubes. Since the 1950 s, many enterprises in China have introduced production equipment and technology from developed countries, but the problems of independent development, application and mass production of neutral borosilicate glass tubes have not been effectively solved. The production technology of neutral borosilicate medicinal glass tubes is in the hands of a few countries such as Germany, the United States, and Japan.

Guarding the National Health

-- Independent development of vaccine bottles

In 2019, relying on the technical advantages of China Building Materials Bengbu Glass Industry Design and Research Institute, China Building Materials Kaisheng Junheng jointly implemented more than 200 technological innovations and conducted more than 1000 technical tests, successfully overcoming core problems such as high-quality melting and high-precision molding, realizing stable mass production of high-quality neutral borosilicate medicinal glass tubes for the first time in China, and promoting the solid chain and strong chain of China's neutral borosilicate glass industry.

Kaisheng Junheng's neutral borosilicate glass tube product quality has reached the domestic leading and international advanced level, becoming the world's fifth and only domestic enterprise that adopts the international advanced "full oxygen combustion" melting process and Dana method to achieve stable mass production of neutral borosilicate medicinal glass tubes.

Bulletproof glass from car

to float glass

And then to the little vaccine bottle.

Process, performance, yield upgrade

More abundant and extensive applications

The miracle created by Chinese building materials people is far more than these

In the Shenzhou spacecraft, large aircraft, aircraft carriers, the Three Gorges Project, etc.

A large number of major national projects and national defense construction projects

Can see the figure of Chinese building materials

Chinese building materials people are constantly contributing to the great rejuvenation of the Chinese nation!

A hundred years of token fire

Hundreds of enterprises and century-old souvenirs have jointly drawn the genetic pedigree of China's industrial development, jointly presenting the forward footprints and memories of the times of the Chinese Communist Party, and vividly depicting the spiritual map of the Chinese Communists. "A hundred years of souvenirs" is an important content and vivid practice for state-owned central enterprises to explore and make good use of red resources and carry out in-depth study and education of party history. On the day of the launch of the "Hundred Years of Pledge" micro-documentary, the State-owned Assets Supervision and Administration Commission of the State Council News Center and the China Central Radio and Television General Station Financial Program Center jointly issued the "Hundred Years of Pledge" theme commemorative first day cover, and with the extensive support of government and enterprise media from all walks of life, integrate online and offline channel resources, and carry out all-media integrated communication.

The 100-episode micro-documentary of "A Hundred Years of Pledge" will be fully disseminated online and offline. The CCTV-2 of the Central Radio and Television Station premieres at 22:00 every Monday to Friday night and rebroadcasts at 12:50 the next day. The official new media platform of the State-owned Assets Supervision and Administration Commission News Center of the State Council, "State-owned Assets Xiaoxin", CCTV Frequency, CCTV Financial Client, Xinhua Client, Learning Times, Qiushi Network, IPTV and other platforms across the country will be broadcast online simultaneously.

In addition, the press center of the State-owned Assets Supervision and Administration Commission of the State Council has also fully integrated the online and offline channel resources of central enterprises and state-owned enterprises. The 100-episode micro-documentary of "A Hundred Years of Credential" will enter 65 Poly Studios, 25 China Resources Vientiane Studios, high-speed train TV, and city subways across the country, it will also be displayed in the ground lounges and air cinemas of Air China, China Eastern Airlines and China Southern Airlines, the business halls of the three major telecom central enterprises, the offline gas stations of PetroChina and Sinopec, the supermarket of China Resources Vanguard and the commercial property sector of China Resources Land, showing the story of red gifts in an all-round way.

Source: China Building Materials Group website

Related News

Share